BY RICK FARMER, NATIONAL HEAD OF MAINTENANCE

Now that the winter season is starting to fade in most parts of the country, pilots everywhere are looking forward to the flying season ahead. If your aircraft has spent the last few months collecting dust, there are few things that need to be checked before you take off for that $100 hamburger.

First of all, make sure that the battery is in good condition and fully charged. The first start after a period of inactivity will put a heavy demand upon the battery, plus it is also beneficial to have enough battery power to help with some additional engine cranking if needed. The best way to ensure a good battery charge is to remove the battery from the aircraft and use a slow “trickle” charger rather than a rapid charger. This presents less risk of damage and more chance of recovering a discharged battery. Rapid charging of a battery can sometimes cause damage by delaminating the cell plates.

Next check the fuel for water. Leaky fuel caps and condensation can cause water to form in the bottom of the tanks or become suspended in the fuel. Water contamination is easiest to find if the aircraft has sat still without any movement, as agitation will encourage the mixing of water and fuel at the boundary where the two meet. It is usually best to check the fuel before moving the aircraft, and then again after moving to allow any trapped water to flow down to the sump points. Be sure to allow at least 30 minutes after moving the aircraft to allow the water time to settle.

Next thing to consider is the condition of the brakes. It is possible they could seize up if the aircraft has been left unused for a period of time, so care should be taken to make sure the brake calipers are free to “float” around the disc with no hydraulic fluid leaks on the ground. Look for signs of a sticky tarlike substance at the pistons behind the brake pads, as this could be an indication of seeping brake piston o-rings where hydraulic fluid has mixed with dirt and debris.

Next thing to consider is the condition of the brakes. It is possible they could seize up if the aircraft has been left unused for a period of time, so care should be taken to make sure the brake calipers are free to “float” around the disc with no hydraulic fluid leaks on the ground. Look for signs of a sticky tarlike substance at the pistons behind the brake pads, as this could be an indication of seeping brake piston o-rings where hydraulic fluid has mixed with dirt and debris.

During your walk-around, remove all the control locks, pitot and static blanks, and any engine blanks that you may have applied to exhausts or inlets. Once removed, perform a thorough check for any “stowaways” that you might have; birds, animals and insects all find dormant aircraft a good place to make their home, so have a good look in the engine bay, in accessible areas of the airframe and pitot and static vents. Some insects use these vents as homes and use the pipe-runs as small breeding areas. What you found as a blockage at the vent opening may only be an indication that there is a further obstruction of insect larvae further down the line that could cause instrument failure.

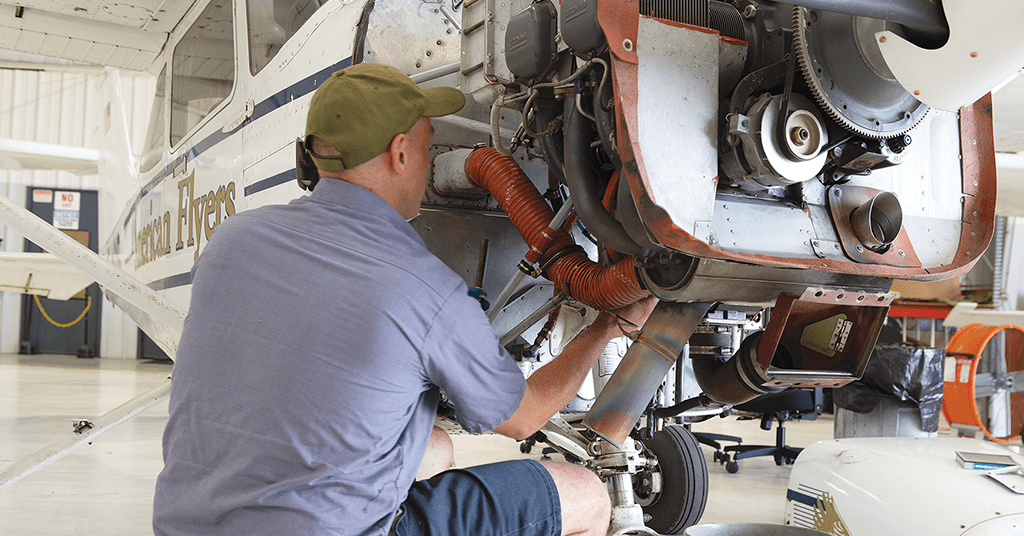

We next need to turn our attention to the engine. If the engine has been stored for several months, it should have been inhibited with a storage oil and desiccant plugs putin place of one set of spark plugs to keep moisture out of the combustion chamber. With these desiccant plugs removed, the engine can be turned over without engine compression offering any resistance. The engine will turn over quite rapidly and allow the oil pump to rotate quickly enough to supply some oil to the oil passages. This will limit the time that the engine will run without full lubrication after engine start. Now replace the spark plugs and start the engine for a brief ground run to warm the oil. This will make the oil more fluid and allow it to drain properly so that it can be changed and replaced with fresh oil.

Once the engine is prepared for the season, you should consider the other areas of the aircraft that might need lubrication. Light aircraft joints, such as flap and control surface operating linkages, and other general purpose applications are normally lubricated by AeroShell Grease 6. Wheel bearings are commonly packed with AeroShell Grease 5. Often these grease application points go for long periods without adequate grease reapplication. If the old grease appears dark and hard in nature, it should be replaced.

Taking time to prepare your aircraft after storage is an important step that will help you to maximize safety and minimize costly repairs later. As an owner/operator, you can perform the preventative maintenance outlined in part 43 appendix A, but it is your responsibility to determine if you are capable of performing the work safely and in accordance with regulations. When in doubt, consult a licensed A&P mechanic.